Description

Advanced Potassium Amyl Xanthate Collector for Sulfide Mineral Flotation

Potassium Amyl Xanthate (PAX, C₆H₁₁OS₂K) represents the next generation of flotation collectors, engineered specifically for challenging sulfide mineral recovery operations. This high-performance collector delivers superior selectivity between valuable sulfide minerals and gangue materials, making it indispensable for copper, lead, zinc, and polymetallic ore processing facilities worldwide.

At Chemicals & Process Equipment Limited, we supply laboratory-tested Potassium Amyl Xanthate (90% minimum purity) manufactured under strict quality protocols for consistent flotation performance. Our PAX collector is optimized for complex ore bodies, offering enhanced kinetics and improved concentrate grades across diverse mineralogical conditions.

✅ Advanced Collector Technology – Superior Mineral Selectivity Performance

✅ Complex Ore Specialist – Polymetallic Circuit Optimization

✅ Fast Kinetic Response – Improved Cell Retention Efficiency

✅ Grade & Recovery Balance – Optimized Economic Performance

✅ Global Mining Standards – International Quality Compliance

Technical Specifications & Chemical Properties

| Property | Specification |

|---|---|

| Chemical Formula | C₆H₁₁OS₂K |

| CAS Number | 2720-73-2 |

| HS Code | 2930.90.90 |

| Molecular Weight | 186.33 g/mol |

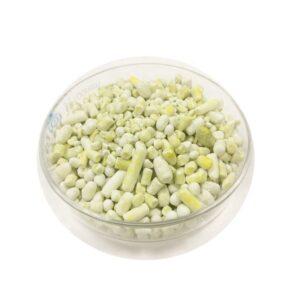

| Appearance | Yellow crystalline powder/pellets |

| Purity | ≥ 90.0% (Flotation Grade) |

| pH (1% Solution) | 9.0-10.5 |

| Moisture Content | ≤ 2.0% |

| Particle Size | Powder: 80-120 mesh; Pellets: 2-4 mm |

| Solubility | Readily soluble in water |

| Bulk Density | 0.65-0.75 g/cm³ |

| Packaging Options | 25kg moisture-resistant bags, 500kg bulk bags, 1000kg containers |

Specialized Packaging Solutions:

- 25kg Multi-wall bags with moisture-resistant PE liner

- 500kg Jumbo bags (FIBC) with discharge spouts

- 1000kg Steel containers for continuous operations

- Climate-controlled storage options for tropical conditions

Flotation Applications & Mineral Recovery

Copper Sulfide Mineral Processing PAX demonstrates exceptional affinity for copper sulfide minerals including chalcopyrite, bornite, and chalcocite. It provides strong collector action while maintaining selectivity against pyrite and other unwanted sulfides, resulting in high-grade copper concentrates with improved metallurgical performance.

Lead-Zinc Separation Circuits In lead-zinc flotation operations, Potassium Amyl Xanthate enables precise control over mineral recovery sequences. It facilitates effective galena flotation while allowing controlled zinc mineral recovery in subsequent flotation stages, optimizing both grade and recovery parameters.

Polymetallic Ore Processing Our PAX collector excels in complex polymetallic ore bodies containing copper, lead, zinc, and precious metals. It provides balanced collection properties across multiple sulfide minerals while maintaining circuit flexibility for sequential recovery operations.

Gold-Associated Sulfide Recovery PAX effectively recovers gold-bearing sulfide minerals, particularly arsenopyrite and pyrite containing precious metals. This application is crucial for refractory gold ores where sulfide mineral recovery precedes downstream gold extraction processes.

Performance Optimization & Dosage Guidelines

Recommended Operating Parameters Optimal PAX dosage varies based on ore mineralogy, liberation characteristics, and circuit configuration. Typical dosage ranges from 10-80 g/t depending on sulfide mineral content and flotation conditions.

Dosage optimization factors include:

- Primary copper flotation: 20-50 g/t for chalcopyrite recovery

- Lead flotation circuits: 15-40 g/t for galena concentration

- Zinc rougher flotation: 25-60 g/t for sphalerite recovery

- Bulk sulfide flotation: 30-80 g/t for polymetallic ores

- Precious metal sulfides: 40-100 g/t for refractory gold ores

For comprehensive flotation collector selection and optimization strategies, refer to this detailed mining engineering guide by OneMine International. Our flotation optimization services provide specialized support for complex ore processing challenges.

Quality Control & Performance Testing

Rigorous Quality Assurance Every production batch undergoes comprehensive testing to ensure consistent collector performance and chemical specifications. Our quality control laboratory employs advanced analytical techniques to verify purity, moisture content, and flotation effectiveness across diverse ore types.

Quality testing protocols include:

- Purity determination via HPLC chromatography

- Moisture analysis using automated Karl Fischer titration

- pH measurement and solution stability testing

- Particle size distribution analysis (laser diffraction)

- Flotation performance testing with standard ore samples

- Batch-to-batch consistency verification through statistical analysis

Storage & Handling Best Practices

Optimal Storage Requirements

- Maintain storage temperature below 25°C in dry conditions

- Protect from direct sunlight and moisture exposure

- Use original packaging until ready for consumption

- Implement proper inventory rotation (FIFO system)

- Ensure adequate ventilation in storage areas

Professional Handling Procedures

- Utilize appropriate personal protective equipment (PPE)

- Minimize dust generation during material transfer

- Provide emergency shower and eyewash facilities

- Train personnel in proper xanthate handling techniques

- Maintain spill cleanup equipment and procedures

Environmental & Safety Compliance

Responsible Mining Chemistry PAX collectors undergo environmental impact assessment and comply with international mining safety standards. The product demonstrates acceptable environmental profiles when used according to recommended practices and dosage guidelines.

Safety Documentation Package

- Complete Safety Data Sheets (GHS compliance)

- Environmental risk assessment documentation

- Transportation classification per UN/DOT regulations

- Workplace exposure guidelines and monitoring protocols

- Emergency response procedures and first aid measures

Advanced Flotation Technology Integration

Process Circuit Optimization Modern flotation plants integrate PAX collectors with advanced process control systems, real-time ore characterization, and automated dosage optimization. This technology integration maximizes recovery efficiency while minimizing reagent consumption and environmental impact.

Research & Development Support Our technical team collaborates with mining operations to develop customized flotation protocols, conduct ore variability studies, and implement process improvements. This support ensures optimal PAX performance across changing ore characteristics and operational conditions.

Why Choose Chemicals & Process Equipment Limited?

✔ Flotation Expertise – Specialized knowledge in complex sulfide mineral processing

✔ Proven Performance – Track record of successful implementations across diverse ore types

✔ Technical Innovation – Continuous improvement in collector technology and applications

✔ Global Supply Network – Reliable availability for international mining operations

✔ Comprehensive Support – From laboratory testing to full-scale implementation guidance

Our Potassium Amyl Xanthate represents the culmination of flotation collector development, specifically engineered for modern mining challenges. We provide complete technical support, from initial ore characterization through process optimization, ensuring maximum value from your mineral processing operations.

For detailed flotation testing, ore-specific recommendations, or technical consultation, contact our mining chemicals specialists. We offer comprehensive services including laboratory flotation testing, pilot plant studies, and full-scale process optimization to maximize the effectiveness of your sulfide mineral recovery operations.

Reviews

There are no reviews yet.